Triple insulation,

triple protection

Triple insulation,

triple protection

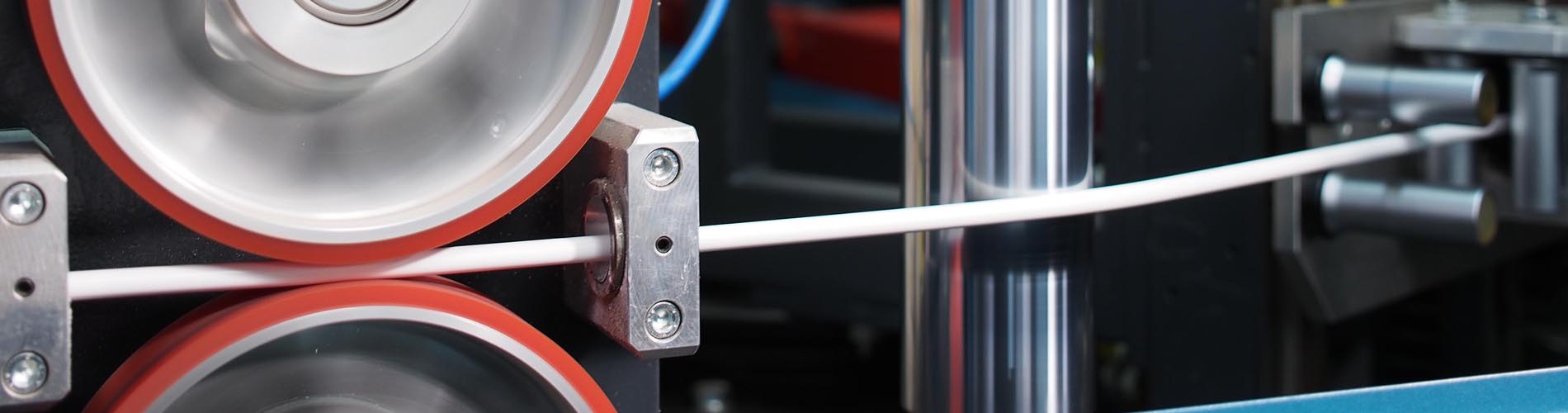

Skin-Foam-Skin from Accordia

Insulation from a solid plastic material (e.g. polyethylene), achieves excellent adhesion to the wire, provides superior mechanical strength and is not vulnerable to moisture, and therefore maintains its characteristics for years. The drawbacks however are that it has a high dielectric constant, low signal speed and higher losses.

Foam plastic insulation has a very low dielectric constant, a high propagation rate and low losses. However, it is difficult to achieve good wire adhesion. The mechanical strength is low and moisture easily penetrates through the porous surface. As a result its impedance changes and the signal losses increase significantly over the years.

Can we have the best of both worlds?

Yes we can! Using Accordia’s three-layer skin-foam-skin insulation technology.

![]()

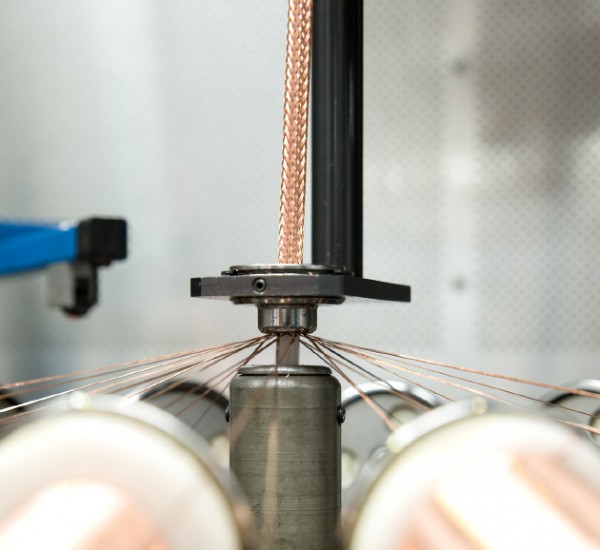

Although the insulation is only 3 to 5 millimeters in diameter, it is made of three distinct layers. The inner layer consists of a mixture of two plastic materials that is designed for perfect adhesion to the wire.

The main layer with a direct injection of nitrogen in high density plastic achieves the lowest possible dielectric constant and therefore higher signal transmission speed without losses.

The outer layer, made of hard plastic of the highest mechanical strength, externally seals the insulation, and offers excellent mechanical strength and protection from moisture.

What we have achieved:

Perfect wire adhesion, easy cable stripping.

Higher signal transmission speeds, lower losses.

High mechanical strength, protection against moisture, durability.

Ιncrease font size

Α- / Α+

Underline links

Increase contrast